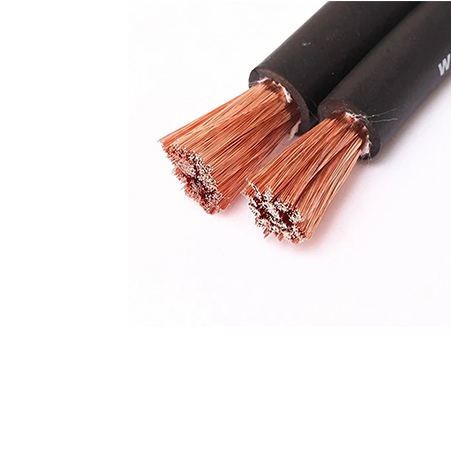

Copper Welding Cables

copper welding cables Spartech International offers a wide range of Copper Welding Cables for various purposes. As manufacturers of Copper Welding Cables, we provide Welding Cable that is made of high grade copper ensuring excellent conductivity. These Welding Cables are ISI marked and thus are designed to meet the set international quality standards. We also have authorized dealers and suppliers of cables in Gujarat , Mumbai and other cities. A copper cable consists of two or more copper wires running side by side and bonded, twisted or braided together to form a single assembly. Electrical cables may be made more flexible by stranding the wires.

Copper wires in a copper cable may be bare or they may be plated to reduce oxidation with a thin layer of another metal, most often tin but sometimes gold or silver. Plating may lengthen wire life and makes soldering easier. Twisted Pair and coaxial cables are made to reject electromagnetic interference, prevent radiation of signals, and to provide transmission lines with defined characteristics. Shielded cables are encased in foil or wire mesh. Further, these cables are available at affordable prices. We also have authorized dealers and suppliers of cables in Mumbai, Gujarat, Delhi and many more cities.

Technical Specification

We cater to your welding requirements of HOFR Welding Cables in the form of Spartech International Welding Cables and Weldcor.

SPM WELD METAL

Technical Specification

| Conductor Area (mm2) | No. & Dia of Wires (mm) | Current Rating Maximum Duty Cycle of 60% (Amps) | Nominal Thickness of Covering (mm) | Max. DC Resistance of Conductor at 20oC (ohms/km) | Voltage Drop (Volt/10m) | ||

|---|---|---|---|---|---|---|---|

| HFOR/TRS | HFOR/TRS | HFOR | TRS | HFOR/TRS | HFOR/TRS | HFOR at 90o | TRS at 60o C |

| 16 | 511/0.20 | 135 | TRS | 2.00 | 1.210 | ||

| 25 | 354/0.3 | 186 | 129 | 2.0 | 1.23 | 1.574 | 0.328 |

| 35 | 495/0.3 | 227 | 159 | 2.0 | 0.901 | 1.153 | 1.045 |

| 50 | 708/0.3 | 287 | 200 | 2.2 | 0.634 | 0.811 | 0.735 |

| 70 | 999/0.3 | 361 | 253 | 2.4 | 0.445 | 0.570 | 0.516 |

| 95 | 1351/0.3 | 438 | 306 | 2.6 | 0.334 | 0.428 | 0.516 |

| 120 | 1702/0.3 | 522 | 365 | 2.8 | 0.256 | 0.328 | 0.297 |

Horf Welding Cables

HOFR Welding Cables are Designed for the secondary (high current) connection to automatic or hand – held metal arc welding electrodes. It is suitable for flexible use under rugged conditions, on assembly lines and conveyor systems, in machine tool and automatically operated line and spot welding machines. SPARTECH INTERNATIONAL, offers a vide range of HOFR Welding Cables for various purposes. As manufacturers of HOFR Welding Cables, we provide Welding Cable that is made of high grade copper ensuring excellent conductivity. These Welding Cables are ISI marked and thus are designed to meet the set international quality standards. We also have authorized dealers and suppliers of cables in Gujarat , Mumbai and other cities.

We cater to your welding requirements of HOFR Welding Cables in the form of Spartech International Welding Cables and Weldcor.

For more information, fill our Enquiry Form.

SPM WELD METAL

High current carrying capacity

high conductor working temperature

More durable (life is more then double)

Excellent ozone and weather resistant

It is heat resisting oil resisting & flame retardant

Low current derating factor at high ambient temperature

Better insulation properties.

Tough

Light, hence suitable for welder.

Saving of lugs as changes are less.

Alluminium Cables

We provide Aluminium Welding Cable of superior quality to attain utmost satisfaction from the customers. The Aluminum Cables that we offer is best in quality and cheap in price. As manufacturers of Aluminum Welding Cables, we provide our customers with best quality cables so as to enable sustainability, durability and resistance. Aluminium Cables To ensure trouble-free performance of the cables in the field, strict quality control checks are carried out at every stage of cable manufacture, from selection & sourcing of raw materials to in-process inspection right up to the finished products and final packing & dispatch of finished goods. Our aluminum welding cables are ISO certified after passing from every test to provide our customers with best quality and satisfaction.

A medium heavy coated rutile type good running Hard Facing Welding Electrodes, deposit a tough air hardening type of weld metal of approximately 350 to 600 BHN hardness.

The weld metal is machinable and recommended for application involving maximum hardness as required.

Typical applications suitable for shear blades brake shoes, coupling, conveyor parts, roller tractor wheels, steel casting, shafts, and axles.

Uses of Alluminium Cables

Hard Facing Electrodes are used for all kinds of gears, shafts, hammers, pulleys, couplings and spindles.

We cater to your welding requirements of HOFR Welding Cables in the form of Spartech International Welding Cables and Weldcor.

For more information, fill our Enquiry Form.

SPM WELD METAL

Features

| Preferred For | Resistance Against | Available Sizes |

|---|---|---|

| Customized Sizes | Chemicals and Acids | 16 sq.mm |

| High Reliability | Oils | 25 sq.mm |

| Flexibility | Weather | 35 sq.mm |

| Safe Usage | Sunlight | 50 sq.mm |

| 70 sq.mm |

Technical Specification

| Conductor Area (mm2) | No. & Dia of Wires (mm) | Current Rating Maximum Duty Cycle of 60% (Amps) | Nominal Thickness of Covering (mm) | Max. DC Resistance of Conductor at 20oC (ohms/km) | Voltage Drop (Volt/10m) | ||

|---|---|---|---|---|---|---|---|

| HFOR/TRS | HFOR/TRS | HFOR | TRS | HFOR/TRS | HFOR/TRS | HFOR at 90o | TRS at 60o C |

| 16 | 511/0.20 | 174 | 121 | 2.00 | 1.210 | 1.555 | 1.409 |

| 25 | 800/0.2 | 228 | 161 | 2.0 | 0.780 | 0.997 | 0.903 |

| 35 | 1114/0.2 | 285 | 201 | 2.0 | 0.554 | 0.708 | 0.641 |

| 50 | 708/0.3 | 360 | 254 | 2.2 | 0.386 | 0.492 | 0.492 |

| 70 | 999/0.3 | 454 | 320 | 2.4 | 0.272 | 0.272 | 0.314 |

| 95 | 1351/0.3 | 547 | 386 | 2.6 | 0.206 | 0.363 | 0.239 |