Hard Facing Electrodes

A medium heavy coated rutile type good running Hard Facing Welding Electrodes, deposit a tough air hardening type of weld metal of approximately 350 to 600 BHN hardness.

The weld metal is machinable and recommended for application involving maximum hardness as required.

Typical applications suitable for shear blades brake shoes, coupling, conveyor parts, roller tractor wheels, steel casting, shafts, and axles.

Uses of Hard Facing Electrodes

Hard Facing Electrodes are used for all kinds of gears, shafts, hammers, pulleys, couplings and spindles.

SPM WELD METAL

Packaging Details

| Sr. No. | Type | Make | Application | Size mm | Photo |

|---|---|---|---|---|---|

| 1 | Hard Facing HF 250 R | D&H, BOHLER | Shaft, Journals, Gear Teeth | 3.20×450 4.00×450 5.00×450 |

|

| 2 | Hard Facing HF 350 R | D&H, BOHLER | Similar application requiring higher hardness. | 2.50×350 3.20×450 4.00×450 5.00×450 |

|

| 3 | Hard Facing HF 650 R | D&H, BOHLER | Crusher jaws, Bucket Teeth, Pulveriser Hammer Cement Mill, cane cutting Knives & Hammer | 2.50×350 3.20×450 4.00×450 5.00×450 |

|

| 4 | Hard Facing HF 250 LH | D&H, BOHLER | Shaft, Journals, Gear Teeth | 3.20×450 4.00×450 5.00×450 |

|

| 5 | Hard Facing HF 350 R | D&H, BOHLER | Similar application requiring higher hardness. | 2.50×350 3.20×450 4.00×450 5.00×450 |

|

| 6 | Hard Facing HF 650 R | D&H, BOHLER | Crusher jaw, Bucket Teeth, Rock crusher Hammer, Ploughs, Cane Cutting knives, & Hammers, Cement mill Hammers. | 2.50×350 3.20×450 4.00×450 5.00×450 |

|

| 7 | Roller Facing Electrodes | D&H, BOHLER | Sugar Mill Rusher Teeth. | 4.00×450 |  |

| 8 | Hard Facing Electrodes, Sunhard 250 (250 BHN) |

JAIN WELDING | Ideal for welding of tram tyres, Gears, Pinion teeths, Couplings, Sugarcane crushers, Hammers and spindle machines etc. | 3.15 mm 4.00 mm 5.00 mm |

|

| 9 | Hard Facing Electrodes, Sunhard 350 (250 BHN) |

JAIN WELDING | Suitable for welding of Couplings, Cog wheels, Cold punching dies, Rail ends and crossings, Steel castings etc. Also find its applications in brake shoes, shear blades, wheels, cams, gears, pulleys, drive sprockets etc. | 3.15 mm 4.00 m 5.00 mm |

|

| 10 | Hard Facing Electrodes, Sunhard 350 LH |

JAIN WELDING | Suitable for bamboo chipper knives. Cane cutting kives,punches,dies,drilling bits, shears and surfacing re building of mill hammers for pulverizing coat. | 3.15 mm 4.00 m 5.00 mm |

|

| 11 | Hard Facing Electrodes, Sunhard 550 (550 BHN) |

JAIN WELDING | Typical application includes welding of metal cutting and forming tool, Shears and croppers, oil expellers, cane cutting knives, Conveyor bucket and mixed blades etc. | 3.15 mm 4.00 m 5.00 mm |

|

| 12 | Hard Facing Electrodes, Sunhard 600 LH |

JAIN WELDING | Typical applications include bamboo chipper knives, Cane cutting knives, Punches, dies, Drilling bits, Shears and surfacing re building of mill hammers for pulverizing coat. Also find applications inMill hammers, Rock drills, Dipper teeths, Shovel Latch Bars, Dump Truck Bodies, Car Couplers, Drive sprockets, Drive shafts etc. | 3.15 mm 4.00 m 5.00 mm |

|

| 13 | Hard Facing Electrodes, Sunhard MN 185 BHN |

JAIN WELDING | Ideally suited for welding of crusher jaw, manganese steel rails, rail cross-overs, cement grinders rings, austenitic manganese steel castings and hammers etc. | 3.15 mm 4.00 m 5.00 mm |

MS Electrodes

We offer a wide range of M S Electrodes with light, medium, medium heavy and heavy coated electrodes, which are used for major and minor structural work. As the name suggests, these electrodes are made for mild steel and are suitable for all welding positions. These electrodes weld the metal, which is of radiographic quality with smooth arc and low spatter.

Uses of MS Electrodes

MS electrodes are most commonly used for out-of-position welding such as field construction, ship yards, water towers, pressure vessels, pressure pipes, steel castings, plain and galvanized steel storage tanks, etc.

SPM WELD METAL

Packaging Details

| Sr. No. | Type | Make | Application | Size mm |

|---|---|---|---|---|

| 1 | E6013 ER4211X (6013 plain) | D&H , BOHLER | All position medium coated rutile electrode with excellent usability characteristics for producing radiographic quality welds. Can be used for pipes & tubes up to 12 mm thickness | 2.50×350 3.15×350 4.00×450 5.00×450 |

| 2 | E6013X ER4211X (6013 "s" x-ray quality) | D&H , BOHLER | All position medium coated rutile electrode with excellent usability characteristics for producing radiographic quality welds. Can be used for pipes & tubes up to 12 mm thickness. | 2.50×350 3.15×350 4.00×450 5.00×450 |

| 3 | E6013XXER4121X (6013"ss" boiler quality) | D&H , BOHLER | A heavy coated all position rutile electrode for deposing heavier welds. Would be useful for application where slower cooling rates are required. | 2.50×350 3.15×350 4.00×450 5.00×450 |

| 4 | E7018 EB5426H3JX (7018-low highdrogen) | D&H , BOHLER | Basic Coated low hydrogen iron powder all position electrode for giving radiographic quality welds subjected to resistant. Resists hot & cold cracking. Weld is strong ductile & though. Suitable for components subjected to dynamic loading. Can be used for pressure parts particularly in thermal plants Metal recovery 115%. | 2.50×350/450 3.15×350/450 4.00×450 5.00×450 |

| 5 | E7018-1 EB5629H3JX [7018-1(7018 spl)] | D&H , BOHLER | Basic Coated low hydrogen iron powder all position electrode for giving radiographic quality welds resistant hot & cold cracking. Welds is strong, ductile & tough down to 45oc. Suitable for components subjected to dynamic loading & pressure parts. | 2.50×350 3.15×350 4.00×450 5.00×450 |

| 6 | E7016 EB5426H3X | D&H , BOHLER | Basic coated low hydrogen iron powder all position electrode for giving radiographic quality for joints subjected to resistant. Suitable for pipe welding application. Metal Recovery Around 100%. | 2.50×350 3.15×350 4.00×450 5.00×450 |

Nickel Based Electrodes

Nickel Electrodes are often used in severe service conditions where extreme heat, corrosion, abrasion, high pressures and combinations of these conditions are present. We produce many grades of nickel, nickel alloy and Copper/Nickel coated electrodes for Arc Welding.

Uses of nickel Electrodes

The flux coating contains various minerals and alloy powders to impart specific welding characteristics and deposit chemistries. Most Nickel base electrodes are produced to the requirements under AWS classification.

Our Range

-

E-Ni1

-

E-NiCr3

-

E-NiCu7

-

E-NiCrMO10

-

E-NiCrMO3

-

E-NiCrMO4

-

Packaging as per ISO Standards

SPM WELD METAL

Stainless Steel Electrodes

We provide Stainless Steel Electrodes. Following are the ranges for the same.

SPM WELD METAL

Packaging Details

| Sr. No. | Brand | AWS | Application |

|---|---|---|---|

| 1 | OK 61.50 | A5.4: E 308-16 | OK 61.50 finds extensive use in fabrication of austenitic stainless steels of 18Cr 8Ni type corresponding to AISI types 301, 304 and 308. |

| 2 | OK 61.30 | A5.4: E 308L-16 | OK 61.30 is especially designed for welding austenitic stainless steels corresponding to AISI 304L, 304, 308L, 308, |

| 3 | ESAB 304B | A5.4: E 308L-15 | ESAB 304B is mainly used for welding stainless steels having a corresponding chemistry with high ductility and high impact values at low temperature cryogenic |

| 4 | OK 61.80 | A5.4: E 347-16 | OK 61.80 finds extensive application for welding of stabilised version of 19Cr/10Ni type steels corresponding to AISI 321 & 347 |

| 5 | ESAB 308H | A5.4: E 308H-16 | Esab 308H finds wide use in the fabrication of components made out of AIS 308H type steels that are used for their high tensile strength |

| 6 | OK 63.30 | A5.4: E 316L-16 | OK 63.30 is especially designed for the welding of 18Cr/13Ni/Mo type steels corresponding to AISI 316 and 316L, 317 type stainless steels. |

| 7 | OK 63.3 | A 5.4: E 316L-15 | OK 63.35 is mainly used for welding stainless steels having a corresponding analysis, but can also be used for welding certain air hardening steels |

| 8 | OK 61.80 | A5.4: E 318-16 | OK 63.80 is especially designed for the welding of Ti and Nb stabilized stainless steels with similar base composition corresponding to AISI 316 and 318 types. |

| 9 | OK 67.67 | A 5.4: E 309-16 | OK 67.67 is designed for applications requiring high strength and corrosion resistance at high temperatures upto 1100°C; for e.g. welding of heat resistant chrome steels |

| 10 | ESAB 309 | A5.4: E 308L-15 | ESAB 309 is specially designed for the welding of AISI 309 type steels, straight chrome steels dissimilar steels |

| 11 | OK 67.60 | A5.4: E 308L-16 | OK 67.60 is essentially used for welding heat resistant straight Chrome steels and Cr-Ni alloyed steels, |

| 12 | OK67.70 | A 5.4: E 309Mo-16 | OK 67.70 is especially designed for welding of acid resisting clad steels and stainless steels to other types of steels |

| 13 | ESAB 309Mo | A 5.4: E 309Mo-15 | ESAB 309Mo is especially suitable for welding of stainless steels where better toughness is required compared to the rutile based electrodes of the same class. |

| 14 | ESAB 309LMo | A5.4: E 308L-15 | ESAB 309LMo is used for the welding of 316 type clad steels as well as for joining and as a buffer layer in welding of dissimilar metals |

| 15 | ESAB 430 | A5.4: E 308L-15 | ESAB 430 is designed for welding AISI 430 stainless steels and steels with similar composition. |

| 16 | ESAB CHROMWELD G | A5.4: E 308L-16 | - |

| 17 | ESAB CHROMWELD G (Spl) | - | ESAB Chromweld G Special is designed for welding of high strength alloy steel and dissimilar joints. |

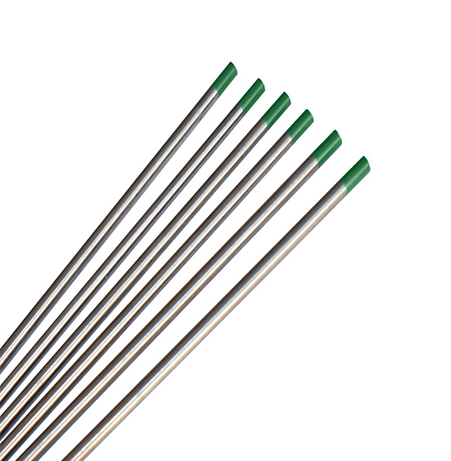

Tungsten Electrodes

Tungsten is the only metal that can meet the high physical and mechanical requirements. Tungsten has the highest melting point of all metals, a low vapor pressure, low thermal expansion, good thermal conductivity and a low electron work function.

Tungsten Welding Electrodes are widely used because they make good welds and are long lasting and quite easy to use. A throated tungsten electrode operates at a temperature well below its melting temperature compared to a pure tungsten electrode. This results in a much lower rate of consumption of the electrode during welding, which eliminates much of the "arc wander" associated with balled pure tungsten. Other reasons for their use include easier arc initiation, reduced weld metal contamination, higher current- carrying capacity, the ability to sharpen the electrode, and long life.

All variety of Tungsten Electrode are packed 10pcs.

We cater to your welding requirements of Tungsten Welding Electrodes in the form of Winner Tungsten Welding Electrodes and Plansee Tungsten Welding Electrodes.

SPM WELD METAL

Packaging Details

| Name of Material | Chemical Composition (Percentage by Weight) | |

|---|---|---|

| W | (pure) | > 99.97 |

| WT | WT20 | 2.0 % ThO2 |

| WLZ | - | 2.5 % La2O3 / 0.07 % ZrO2 |

| WL | WL10 | 1.0 % La2O3 |

| WL15 | 1.5 % La2O3 | |

| WL20 | 2.0 % La2O3 |

Low Hydrogen Electrodes

Low hydrogen electrodes, often referred to in welding, are designed to minimize the amount of hydrogen that can enter the weld pool. This is crucial in preventing hydrogen-induced cracking, especially in high-strength steels or in applications where the welded joint will be exposed to harsh environments.

SPM WELD METAL

Packaging Details

| Sr. No. | Type | Make | Application | Size mm |

|---|---|---|---|---|

| 1 | SUNTHERM 7016 E 7016 |

JAIN WELDING | Joining of Mild steel with Cast Iron, welding of HT52W and high tensile grade steels, also used as buffer layer before hard facing. | 2.50 mm 3.15 mm 4.00 mm 5.00 mm 6.30 mm |

| 2 | SUNTHERM 7018 E 7018 |

JAIN WELDING | Stronge tanks, Dynamic loaded structure, Pressure Vessels, Boilers, Penstocks, Railway Wagons, Blast furnace shells. | 2.50mm 3.15 mm 4.00 mm 5.00 mm 6.30 mm |

Cutting & Goughing Electrode

Cutting and gouging electrodes are specialized welding consumables designed for removing metal in various applications. They offer a versatile and efficient alternative to traditional methods like oxy-acetylene cutting or mechanical removal.

SPM WELD METAL

Packaging Details

| Sr. No. | Type | Make | Application | Size mm |

|---|---|---|---|---|

| 1 | SUNCUT | JAIN WELDING | Recommended for cutting of various grades of steels such as mild steels low alloy steels, stainless steels and cast iron. There is no need of any supplementary gas like oxygen/acetylene or compressed air. Piercing of metals can be done in all positions. | 3.15mm 4.00mm 5.00mm |

| 2 | SUNGOUGE | JAIN WELDING | Suitable for cleaning fins and risers, removal of cracks ,sand pockets and defects in foundry,casting,back gouging, barreling in fabrication of all industrial metals. Also used to remove unwanted metals prior to final machining. | 3.15mm 4.00mm 5.00mm |

Welding Testing

We offer DP Test Chemicals, PP-15B PMC Flawcheck Dye Penetrant Chemical,

PMC Instacheck Penetrant, Fluorescent Dye Penetrant and Dye Penetrant Testing Chemical from India.

The PMC Products Advantage

Client retention by Hi-Performance & Prompt service

45+ years experience to assist

World wide Distribution Network

World & Indian standard certification

ASME Boiler & Pressure vessel code

ASTM-E-165, AMS, ISO 9001, RDSO, IGCAR, NPCIL, NSD

SPM WELD METAL

SPM WELD METAL

The PMC Anti-Spatter products

The anti-spatter spray contains a silicone or similar ingredient that is typically a petroleum-based or water-based solvent that prevents the spatter from sticking.

PMC GEL-PG-1

PMC FLUID-PG-2

PMC SPRAY-PS-1 Silicon base

PMC SPRAY-PS-2 Non Silicon base

Features

| P-MWET product | Bright Colour Contrast | Long Shelfife |

| Non-Toxic | Good Area Coverage |

The PMC Suraksha

PMC

DISINFECTANT SPRAY

Packing 1 Lit / Aerplsol Can

Features

| P-MWET product | Bright Colour Contrast | Long Shelfife |

| Non-Toxic | Good Area Coverage |

SPM WELD METAL

Tested Perfomance by PMC